Energy Software Development for Efficient Energy Management

Custom energy software development helps businesses manage processes and workflows more effectively. We optimize consumption in smart grids, improve operations in renewable energy plants, and enhance performance in energy storage systems like battery networks, hydropower facilities, and beyond.

100 +

Projects

400 +

Publications

Energy Software Development for Efficient Energy Management

Custom energy software development helps businesses manage processes and workflows more effectively. We optimize consumption in smart grids, improve operations in renewable energy plants, and enhance performance in energy storage systems like battery networks, hydropower facilities, and beyond.

100 +

Projects

400 +

Publications

Our Energy Software Development Services

Renewable energy software brings efficiency to energy systems by addressing problems such as energy storage, distribution, and demand planning. These advanced solutions improve resource management, stabilize grids, and support the integration of solar, wind, and other renewable energy sources.

About Us

We are an energy management software development company dedicated to innovation. With over 10 years of experience, we develop solutions that improve energy efficiency, advance green technology, and deliver reliable systems.

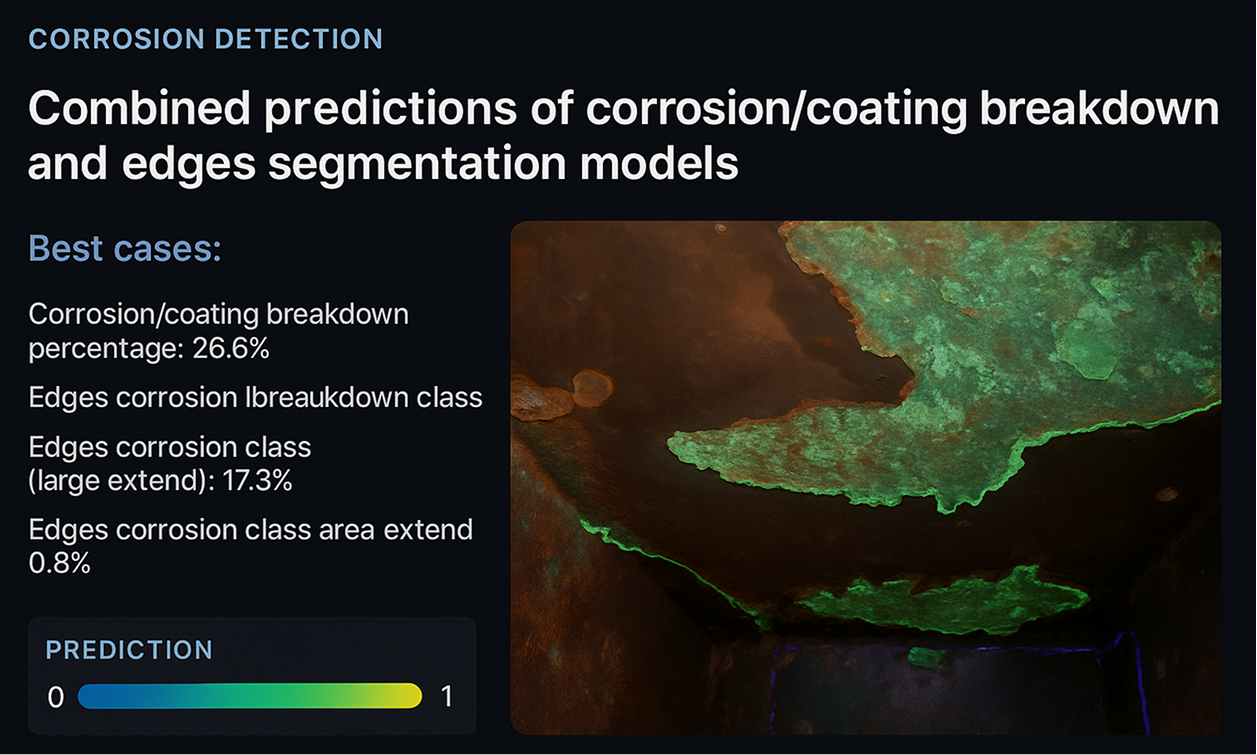

Our team has worked on projects such as real-time corrosion detection for offshore platforms, achieving 100% accuracy in rust identification and enabling faster maintenance.

Our Awards & Certifications

Our expertise in energy sector software development has been recognized by leading organizations. With certifications and industry awards, we deliver solutions that combine cutting-edge technology with proven industry knowledge, ensuring impactful results.

Straight

to

business?

Get a Qualified Consultation from an Expert

Why Choose Us for Renewable Energy Software Development?

We help businesses in the energy sector adopt modern technologies. Our solutions focus on performance, reliability, and achieving business and operational goals.

Crafted by Experts

-

Our energy software development services are led by professionals with deep expertise in the field.

-

For instance, we’ve developed predictive maintenance solutions that achieved 99.9% accuracy in detecting faults in energy equipment.

Value-Driven Partnership

-

Renewable energy is about long-term value.

-

Our software supports your business goals while promoting sustainable growth.

-

For example, our green energy solutions helped companies reduce energy costs by integrating AI and big data analytics.

Certified Professionals

-

Our team includes certified experts who bring proven knowledge and practical skills.

-

Their expertise ensures your project is in the right hands.

Efficient Structure

-

Our approach eliminates extra management layers, ensuring clear and direct communication.

-

This minimizes delays in responses and decision-making, allowing projects to progress smoothly and efficiently without unnecessary complications.

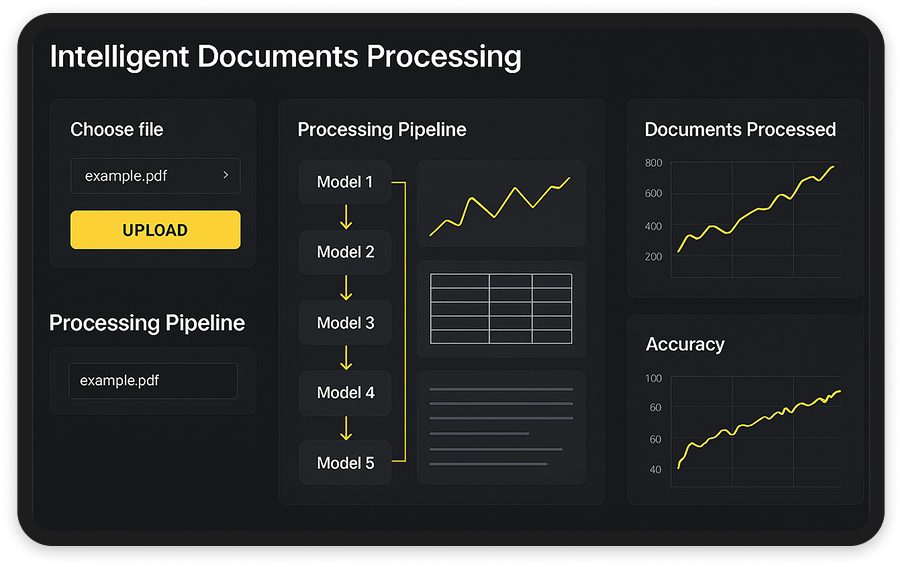

Successful Energy Software Projects Developed by Us

Uncover how our energy software expertise translates into successful, client-focused projects. These achievements highlight our dedication to creating smarter, greener, and more efficient energy solutions.

Intelligent Documents Processing

Corrosion Detection

What Clients Say Аbout Our Solutions

Our renewable energy software solution has helped businesses overcome challenges, reduce operational costs, and improve performance. Clients value our commitment, innovative approach, and ability to deliver results that align with their goals.

Straight

to

business?

Get a Qualified Consultation from an Expert